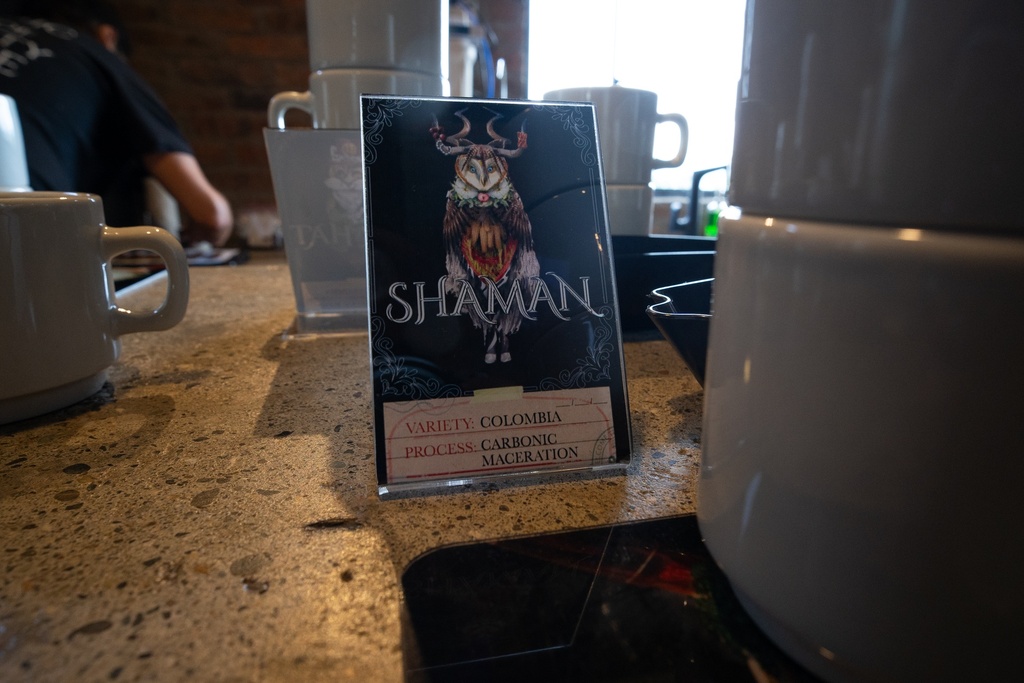

El Embrujo Shaman Carbonic Maceration

أمبريخو شامان

Ignacio Rodriguez’s father purchased the first 12 hectares of Finca La Palmera over 50 years ago. Through tireless work, he continued expanding the farm, which reached 170 hectares by the time Ignacio inherited it. Today, Ignacio applies the same spirited focus to producing specialty-quality coffees.

The name “embrujo” comes from the Spanish word for “spell”. Ignacio believes that truly excellent specialty coffee will evoke the “magic of coffee” for drinkers. To this end, he is focused on transitioning from traditional agriculture to a more specialty focus. Ignacio is building a laboratory and microbiology lab to help him better understand the process at the biological level and ultimately improving his processing for consistency and flavor.

Ignacio employs 48 women year-round. These women, many of whom are single mothers supporting their families, ensure high-quality by sorting cherry and parchment to remove any defective beans.

Igancio saves the pulp from processing his washed process coffees and applies it to coffee trees as fertilizer. He is planning to use vermiculture to further process pulp into nutrient-rich fertilizers. Water from processing is used to irrigate his corn crops. The processing operation is fueled entirely by renewable energy from solar panels. Another change Ignacio is making to ensure the highest quality and most sustainable processing is transitioning to lower water- use processing, like this Natural. In addition to coffee, Ignacio also grows avocados and maize.

For Shaman,Cherry is placed in stainless steel tanks and CO2 is injected into the tanks. The tanks, installed in 2022, can hold up to 4,000 kgs of cherry. Most processors in Colombia use 20kg plastic barrels for fermentation, so this larger capacity tank has the potential to create much more uniform extended fermentation lots.

Typically, during fermentation, microbes ingest oxygen and emit CO2. When CO2 is injected, the microbes that consume CO2 become more active and that creates a different flavor profile that=n typically aerobic microbes. Cherry ferments in this CO2-rich environment for 120 to 140 hours.

Cherry is dried in mechanical dryers. Using mechanical dryers enables Ignacio to control the temperature and makes it possible for him to process coffee consistently on a larger scale. Once dried, coffee is placed in Grainpro bags and rested before being prepared for export.